| Previous Page | Table of Contents | Next Page |

POTLATCH PROUD OF VPD SAW RESULTS

Potlatch Corporation has stood at the forefront of new saw filing technology for years. The management and sawmill personnel at the 71-year old Clearwater Lumber Division sawmill in Lewiston, Idaho are committed to fine tuning their programs to increase production, reach higher recovery goals and enhance the quality of their product.

"The VPD saw teeth were stronger and easier to maintain" |

The mill began Stellite tipping and side grinding band saws when that technology was still being proven. They installed two No. 85 Armstrong AUTOTIP automatic Stellite tipping machines and two No. 90 Armstrong EQUALIZER dual side grinders to enhance their already sound filing program. They found that Stellite tipped and side ground saws were tougher and kept a sharper edge than swaged and shaped band saws, which meant smoother sawing, better finish on the boards and less repair work for the filers and fitters. This program led to increased recovery in the sawmill.

Head filer Loren Young reports that four years ago they were having problems maintaining feed speeds without getting washboard or rough cut lumber. Potlatch saws between 550,000 and 950,000 board feet (1294 to 2235 cu. meters) of cedar and hem fir per day in the 2-shift mill.

|

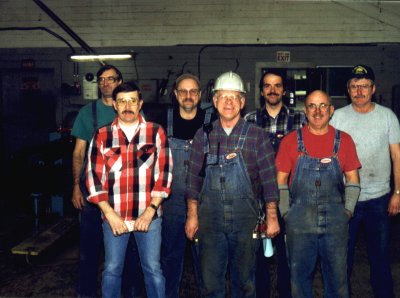

| Two shifts in Potlatch’s filing room maintain over 100 saws a day. The day shift crew includes from left to right, Richard Bowden, Vern Tietz, Dave King, Loren Young, Leonard Jones, Larry Weaver and Gary Wells. Night crew members Phil Tyler, Gary Hayes, Bob May, Rick Campbell, Don Welch and Larry Nelson are not pictured. |

Loren worked with Scott Emmert of Saw Performance Specialists and Mike Cloutier of Whatcom Saw to begin sharpening variable pitch band saws. There was proof that saws with variable pitch (VP) teeth dampened harmonic vibration, resulting in faster feed speeds, less wash board and smoother lumber than conventional, evenly spaced, saw teeth. Other mills trying these saws also found that kerf and target sizes were reduced.

Loren didn’t want the added expense of converting all six of their No. 4 sharpeners without firm proof of what VPD saws would do for the mill. With assistance from Missoula Saws, he rented a No. 4 VPD grinder from Armstrong to grind a 5-tooth "segment" varying both the pitch and depth of the saw teeth.

"We’ve improved our sawing accuracy |

Even better sawing performance was achieved with the new saw tooth design. The Variable

Pitch and Depth (VPD) saw teeth were much stronger and easier to maintain than the saws he

had run with just variable pitch. Loren’s initial research already showed positive

results.

|

| Larry Weaver uses a star dresser to cut in a frost notch on his grinding wheel. All band saw sharpeners have Armstrong ShapeUp wheel dresser/truing systems to quickly shape wheels to the head filer’s specifications. |

He purchased a VPD conversion kit for one of his No. 4 Armstrong band saw sharpeners

and was trained to install it at Armstrong. He ordered and installed five more kits to

convert his remaining five No. 4 sharpeners to VPD. And he is proud of the results.

"We cut faster with no wash boarding" |

"We've improved our within board sawing accuracy by .010" by upgrading from conventional band saws to VPD saws," states Loren. "We cut faster with no wash boarding and our saws hold up better," he continues. Loren also reports that his filers get more regrinds per Stellite tipping than before.

All of Loren’s No. 4 VPD band saw sharpeners are installed with SideWinder feed arms and StrongArm II air clamps for improved grinding stability, poly-v belt drive to eliminate belt slippage and help reduce vibration, phase inverters to change the grinding wheel speed and ShapeUp wheel dressing/truing systems to quickly shape the wheels to exact specifications. "We maintain our wheel shape more consistently and have reduced our wheel consumption. We are also getting more regrinds on the Stellite tips," explains Loren.

Loren and his 13-man filing crew find they can consistently turn out superior saws with all the upgrades they have made the past few years.

BAND SAWS

QTY. |

MILL DIA. |

GAUGE |

KERF |

1 |

9 Ft. Double Cut Band Mill |

13 GA. (2.41 MM) |

.175" (4.44 MM) |

2 |

6 Ft. Quad Mills |

16 GA. (1.65 MM) |

.130" (3.30 MM) |

1 |

6 Ft. Twin Resaw |

16 GA. (1.65 MM) |

.130" (3.30 MM) |

1 |

6 Ft. Horizontal Twin Resaw |

16 GA. (1.65 MM) |

.130" (3.30 MM) |

All band saws are Stellite tipped and side ground, with the exception of the 9-ft. double cut, which is swaged and side ground. All are changed every four hours. The rotary gang and board edger saws are also Stellite tipped and changed every 8 hours and 16 hours respectively.

Loren Young has been at the Lewiston sawmill for 31 years. After working his first five years in production, he began work in the filing room and later became head filer.

When asked what advice he could give to filers starting VPD sawing, Loren said " Get all the information you can and look at what you want to improve. . . feed rates, vibration or wash boarding problems or getting better recovery rates. VPD will definitely improve your sharpener and ultimately lead to better sawing performance."

| Previous Page | Table of Contents | Next Page |