| Previous Page | Table of Contents | Next Page |

STELLITE� PROGRAM SUCCESSFUL AT EASTERN CANADA SAWMILL

Fawcett Lumber in New Brunswick underwent a major expansion in 1997 to increase production. Stellite tipped circle saws helped them achieve their goals of faster feed speeds while reducing down time.

In the mill, they added a second, high speed Valen Kone debarker, two Linden step

feeders, a Valley Machine canter twin, and ten log sorting decks with Autolog scanner

system. In the filing room, they added an Armstrong Autotip automatic Stellite tipping

machine and began Stellite tipping their circle saws.

|

| Kelly Crossman checks the anneal on a gang edger saw at Fawcett Lumber. Stellite tipped saws feed faster with less deviation than carbide. |

"Once the equipment was up and running, we were setting production records every

week" said Robert Fawcett, Operations Manager at the mill. "Overall production

increased 55% - from 90,000 board feet to 140,000 board feet (215 to 335 cubic meters) per

9-hour shift. Our best shift to date is 190,000 board feet (445 cubic meters)."

"We looked at all the equipment available to Stellite tip our gang edger and canter twin circle saws. We process a high number of gang edger saws in our filing room so we realized we need a machine that performs accurately and consistently" he continued. "The gang edger was originally built to run at 200 feet (61 meters) per minute. We modified it to run at 490 feet (150 meters) per minute."

"When we ran carbide, we were never able to hit our target size consistently, running at the speed we needed to get our piece count of 25,000 cants per day. With Stellite the saws feed faster, with less deviation, and we hit our target continually" said Robert.

"Stellite saws feed faster, with less deviation" |

Kelly Crossman and Dave Mann tip the saws. Both have been at Fawcett for 12 years.

"The Autotip is fast, accurate and consistent" said Kelly. Dave likes that he

can set the machine to run, then walk away and work on other jobs while the Autotip runs.

"It is also good when we have a lot of saws to tip in a short amount of time" he

said.

They chose the Armstrong PRO-Filer II sharpener and TrueSizer side grinder to round out

the package. "We get a consistent top & face on the tooth every time with the

PRO-Filer II" said Robert.

|

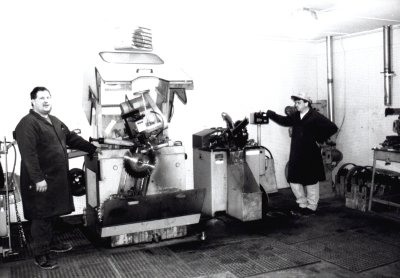

| Dave Mann (left) sharpens the saws on the PRO-Filer II circle saw sharpener and Kelly Crossman side grinds them on the TrueSizer dual side grinder. Kelly and Dave sharpen forty 16" diameter X .090 plate X .125" kerf gang saws everyday. |

Production Manager Dale Douthwright and Maintenance Supervisor Harold Garnett have been

very supportive about the changes in the filing room. "They both have a lot of

sawmill experience and realize the success of the filing room reflects on the whole

operation" said Robert.

About six months after the new equipment was started up, Garnett attend

Armstrong’s 3-day Stellite Workshop covering the electronic, hydraulic and mechanical

systems of his new machines. "Harold received excellent training and troubleshooting

experience from the workshop. I would recommend every sawmill running Stellite send at

least one person" said Robert.

"Overall production increased 55%" |

Fawcett Lumber, which includes a studmill, dry kilns and planermill, is a family-owned, three generation business, founded in 1931 by Henry A. Fawcett. He was joined in the business by his son George in 1949 who remains active as president today. George’s sons Robert, Tim and Henry joined the business in the mid-70’s and are responsible for the day to day operations.

"The lumber business is tough. We must always be striving for better results today, then we got yesterday. You must have people on staff who are committed to dealing with constant change. In order to survive we have to find ways to get more lumber out of each log" said Robert. "With Stellite, we are doing just that."

| Previous Page | Table of Contents | Next Page |