| Previous Page | Table of Contents | Next Page |

New Technology Proves Successful at Crown Pacific

"In order to produce good quality lumber, we needed to upgrade our filing room equipment," said Larry Averett, filing supervisor at Crown Pacific's Gilchrist, Oregon sawmill. "We had to get our machinery in good running condition, otherwise we were just fighting a losing battle."

Crown Pacific took the steps to equip their filing room with the best technology available. First, they did their homework. "We learned a lot about VPD (Variable Pitch and Depth) technology and the good results sawmills were achieving with VPD," said Larry. "We wanted to feed faster, improve our quality, and increase our recovery".

|

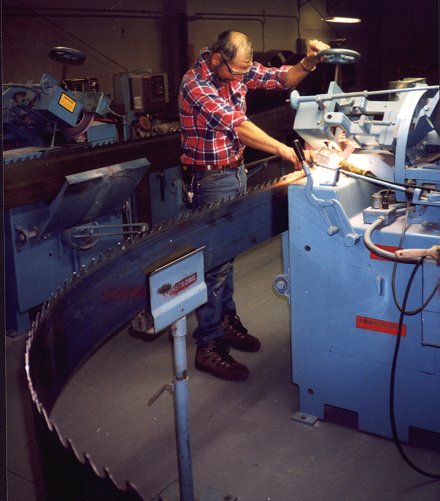

| Craig Hansen adjusts a No. 4 Armstrong sharpener that has been especially equipped for sharpening band saws. Since changing to VPD the standard deviation at Crown Pacific has dropped 42%. |

They installed two Armstrong No. 4 VPD Band Saw Sharpeners in October '98 and two more just three months later. Prior to that time, they were running some standard tooth space saws and some variable pitch saws.

"VPD saws feed faster and quality is better" |

"VPD saws cut straighter with less washboard and the saw teeth are easier to maintain," said Larry. "Since we changed to VPD, our standard deviation on all machine centers has dropped 42%. The average deviation on an "L size" program is right at .015" (.38 mm). We are feeding faster and our quality is much better."

Crown Pacific also replaced a European leveler with an Armstrong automatic band saw Leveler. "The wrecks and lumps in our band saws can almost be completely leveled now with the Armstrong automatic Leveler," said Larry. "It saves us a lot of time at the bench. The automatically leveled saws are flatter and they cut better"

|

| Mike Vantrease prepares to Stellite tip a band saw on the Armstrong Autotip. "Stellite tipping is more work than swaging saws, but the saws come back in better shape" said Head Filer Larry Averett. All the saws at Crown Pacific are Stellite tipped on an Armstrong tipper. |

All the band and circle rip saws at Crown Pacific are Stellite tipped on Armstrong No. 85 Automatic Stellite Tippers. "Stellite tipped saws cut sharper than swage tooth. They saw faster with less deviation" said Larry. "Stellite tipping is more work than swaging saws, but the saws come back in better shape, so they require less benching time."

Larry has seen the successes with Stellite for some time. "Stellite is a big improvement for the industry. We are able to produce sharper saws with smaller kerfs, than with swage tooth saws. The improved production, quality and recovery gains we achieve with Stellite helped keep us in the black during the tough market in 1998. We continue to improve on those good results."

Craig Hansen and Mike Vantrease tip and side grind the VPD band saws. Every day eight 14 gauge X 10" (254 mm) wide X .140" (3.5 mm) kerf, eight 15 gauge X 9" (225 mm) wide X .130" (3.3 mm) kerf, and 12 .068 plate X 9" (225 mm) wide X .120" (3 mm) kerf are processed through the file room.

"Stellite helped keep us profitable" |

The sawmill cuts Ponderosa and Lodgepole Pine during two 8-hour shifts per day. They are currently producing 500,000 board feet (1200 cubic meters) of lumber every day. Production has increased substantially over the last three years. "We continue to meet or beat our production goal of 10 million board feet per month," said Larry.

|

| Lead Filer Dave Londborg inspects a saw tooth prior to it being ground on the Armstrong No. 4 VPD Sharpener. "VPD saws cut straighter with less washboard" said Larry Averett. |

Larry came to Gilchrist in March of '98 bringing with him over 23 years experience in the filing room. He has filed in many mills in the Northwest USA in his career including Idaho, Montana, Oregon and Washington. He is also the past president of the Intermountain Saw Filers' Association.

"With VPD, Stellite, and proper machine maintenance, we are able to get good results and improve the quality of our product," said Larry, "In the end that means more profit for the sawmill"

| Previous Page | Table of Contents | Next Page |