| Previous Page | Table of Contents | Next Page |

Venturing into unknown territory with new production demands while still satisfying environmental concerns is a big task.

Brazil’s Aracruz Wood Products confidently did all three when they opened a new high-tech sawmill in Posta de Mata in the state of Bahia, Brazil in March 1999.

|

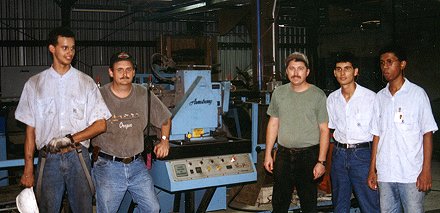

| Aracruz Wood Products high-tech mill combines filers from Brazil and the U.S. during start-up. From left to right: Clayton Douglas, Ellis Ralls, Dennis Jones, Carlos Santos and Bruno Silva. |

Already one of Brazil’s top exporters in the pulp market, Aracruz Celulose, S.A. recognized the growing demand for sawn hardwood products, especially those produced from renewable resources. They recently developed Lyptus� , a high-grade hardwood derived from eucalyptus hybrids used for furniture, cabinets and flooring marketed in Brazil and Europe.

Using plantation trees exclusively to produce Lyptus, logs from the native forests are never used in Aracruz’ lumber manufacturing.

The state-of-the-art sawmill is a "prototype" plant, the first in the Southern Hemisphere to convert eucalyptus into high quality lumber.

|

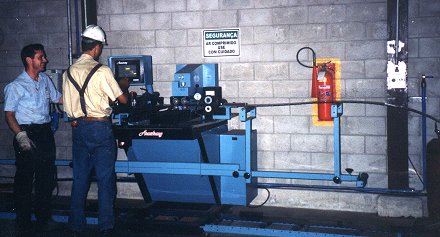

| Montana-based Scott Emmert watches as Clayton Douglas checks the settings on the band saw leveler. The touch screen control provides the operator information about the condition of the saws. |

Aracruz’ General Manager, Carlos Gilberto Marques worked with Oregon-based consultant and project manager, Gary Cantrell, to recommend equipment for the filing room. The company chose all Armstrong equipment including a band saw leveler, side grinders, sharpeners and stretcher roll benches for both the band and circle saws.

"We wanted equipment from one firm to get the best value for the dollars spent," stated Gary. "Armstrong equipment is used all around the world with excellent results."

"Acid in wet wood forced switch to Stellite" |

They originally swaged, shaped and side ground the bands with good success because they were sawing logs that had air dried for a few months. But the acid in wet wood dulled the steel so severely, that they switched to Stellite� tipping the saws. An Armstrong No. 85 Autotip was chosen partly because it could also tip circle saws in the future.

|

| Carlos Santos and Scott Emmert share ideas about tipping saws, while Clayton Douglas manually jogs the No. 85 AUTOTIP through set-up procedures. |

"Sawing eucalyptus poses a greater challenge than most North American hardwoods because there are varying degrees of hardness and stresses in the wood and resin pockets to deal with," noted Head Filer Ellis Ralls. With 28 years experience in the sawmilling industry in the States, Ellis was hired to set up the filing room and help train the local filers. Ellis and other experienced U.S. filers have worked with the Brazilian filing team for several months.

The saw shop crew maintains all saws for the 6 ft. McDonough headrig and 6 ft. resaw, one 3-saw board edger, planer and sawmill trimmers. The 15 gauge, .140 kerf bandsaws are all Stellite� tipped. The edger and trim saws are carbide tipped.

|

| Fitter Carlos Santos checks the tension on a 40 ft. long head saw at the Armstrong benching station. Scott Emmert looks on. |

The sawmill and filing room run two nine-hour shifts, with two scheduled saw changes per shift. Ellis points out that by Stellite tipping, "we had fewer unscheduled saw changes."

Current production is over 8,500,000 board ft. (20,000 cu. meters) per year, with targeted plans of four times that amount at full capacity.

"When Phase II of the project (adding another headrig and edger) is completed, this facility will be equal to the largest hardwood mill in North America," concludes Ralls.

The Saw Engineer congratulates Aracruz Wood Products for their accomplishments and extends special thanks to Ellis Ralls and Gary Cantrell for assisting with the article and Gary Langston and Scott Emmert for providing the photos.

| Previous Page | Table of Contents | Next Page |