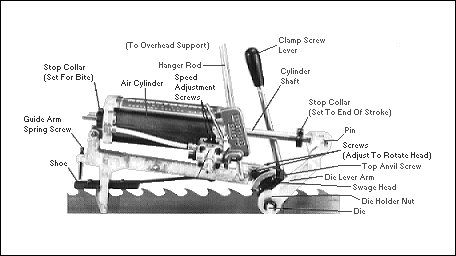

| Setting

Head to Tooth

- Set swage on saw. Run saw through slot in swage head

and rest shoe on saw tips. Remove die from die hole and look to see if flat end of

anvil is sitting flat on tooth with no light at either front or back of anvil.

- To adjust, loosen two screws holding guide arm and rotate

head forward or backward until anvil sets flat on back clearance of tooth.

- Tighten screws in guide arm. Recheck.

Setting Die Lever to End of Stroke

|

1. Assemble die holder, handle and die

holder nut snugly.

2. Insert into die hole and rotate lever counter-clockwise until eccentric

die contacts anvil. |

3. Slip die lever on die

holder until a comfortable swaging position is reached.

4. Remove lever and die assembly. Tighten nut on die holder. Then

replace in die hole. Mark die lever to correspond with split in die holder for ease

of re-establishing setting and as a reference if die holder should slip in lever.

5. Move die lever forward until eccentric die contacts anvil.

6. Move die lever back slightly (about 1/16"). Set front stop by

bringing it up against the die lever and tighten.

7. It is important to set front stop to hold eccentric die away from face of

anvil to avoid damage to die or anvil. |

|

Set Front

Guide Arm Spring Screw

|

1. Set gap between end of the screw and

guide arm spring if it is desired to pull the tooth point down.

2. Pulling point down will permit heavier grinding on back of tooth, if

necessary to maintain tooth shape. |

Setting Stop Collar For Bite

- Set swage on saw and line up eccentric part of die by eye so

it will pick up about 1/8" or 3/16" of tooth.

- Set stop collar (farthest from swage head) by sliding it back

and forth along the cylinder shaft. Toward cylinder reduces bite, away from cylinder

increases bite.

- Swage tooth.

- Adjust stop for more or less bite.

WARNING: Avoid contact

with the air cylinder shaft when air supply is connected to swage. You are working

in a dangerous environment. To minimize risk of injury, keep your work area clean

and all tools in good working condition. |

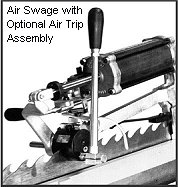

Additional

Recommendations for Air Swages

|

1. Use 1/4" air hose. We

recommend 80 lbs. maximum and 60 lbs. minimum.

2. Use an air regulator and gauge to control pressure, in addition to the |

usual shut-off valve in the air

line. This allows precise control of the air pressure. The regulator and gauge

should be placed in the air line near swage operation, but not attached to the swage.

3. The piston in the air cylinder is fastened to the piston rod with a

shearing pin. In the event of an accident or excessive air pressure, the pin shears

off, releasing the piston and preventing possible damage to parts.

4. Armstrong has air valve repair kits available (Part No. 5352-R) or you can

send air valves directly to Armstrong for repair.

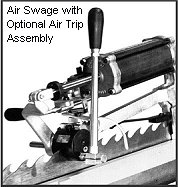

5. Armstrong manufactures an optional air trigger conversion kit or

"trip assembly". Refer to photo. (Part No. 6276-C1)

6. Speed of cylinder stroke can be controlled by two screws located on the

valve (see front photo) - one for each direction. Note: Swaging too quickly can

cause tooth crumble. Keep your stroke smooth and steady. |

DIE SELECTIONS: |

| Long |

The long bite die is the mildest

die, and produces the smallest kerf. |

| Short |

The short bite die is the most

frequently used for "average" conditions. |

| Extra Short |

The extra short die is the most

aggressive, giving the heaviest kerf. |

|

Maintenance Armstrong Air Swages require very little

maintenance. Regular cleaning is the key to keeping a good, accurate, reliable tool.

Swages have a number of parts that are consumed during swaging and need to be

replaced. Don't wait until you are having difficulties to replace them.

- Keep spare parts on hand and use carbide whenever

possible. Carbide lasts longer, works better and costs less in the long run.

- Keep swage valve and cylinder well lubricated using the

lubricator supplied with each swage or you may wish to use an in-line oiler attached to

your air source.

- Make sure only clean, filtered air is directed into the swage

cylinder.

- Wipe swage down and inspect for loose parts and wear at least

once a week. When the die shows signs of wear, move it over 1/4" minimum.

- Refer to Armstrong's "Back to the Basics" Swage and Shaper

Troubleshooting Guide for more detailed information and answers to many commonly asked

questions.

Suggested Overhead

Support Method

Place Trolley rail high enough so not to

interfere with handling saws (approximately 7 feet). To lift swage up and out of the

way when not in use, arrange a small rope and sheave from higher up with end of line and

attach to swage loop "A". |