| Armstrong's CNC Wheel Dresser | ||

|

|

|

|

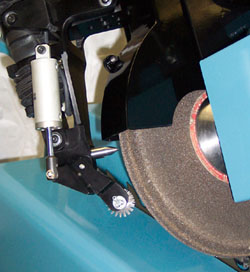

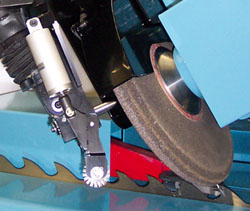

Two-stage Shaping and Dressing: first a diamond cutter shapes the grinding wheel and then a �star� dresser �opens� the wheel for faster and cooler cutting action. The operator selects the stock removal and number of passes of the diamond and stars to consistently produce the grinding wheel shape and surface you want. Automatic

Infeed:

the operator can select the number of grinding passes desired and how

frequently the wheel should be dressed on the VariSharp.

The computer compensates for wheel wear while it follows your

instructions. The

operator can even select to take a very light final pass with the

VariSharp at a slower speed to produce exceptionally sharp band saw

teeth. |

More Fully Automates the VariSharp Grinder: since the operator does not need to make any adjustments once grinding has started. One operator can easily run two CNC VariSharp grinders. Or a benchman (especially one using an automatic Leveler or automatic bench) can also run the CNC VariSharp grinder. Trues the Grinding Wheel: the CNC wheel dresser maintains the wheel rim concentric to the grinding wheel arbor. The wheel grinds with the entire periphery for faster stock removal, better finish and less vibration. The CNC wheel dresser complements the larger grinding wheel motor, heavy-duty one-piece grinding wheel arbor and bearings, and the low-vibration poly-V drive belt that are standard on all new Armstrong CNC VariSharp grinders. |

||||||||||||

|

|

|||||||||||||

| Armstrong's CNC Wheel Dresser | |||||||||||||

|

|||||||||||||